Guangzhou Victory Technology Co., Ltd., headquartered in Guangzhou, China, stands as a pioneer in energy storage technology applications. We specialize in products for industries such as automotive, electric vehicles, and tourism, offering a range of dry batteries, lithium-ion batteries, and home energy storage systems. Our products are certified by internationally recognized standards including KC, CB, CE, PSE, FCC, RoHS, and UN38.3, ensuring they meet global safety and quality requirements. With a strong international presence, leveraging continuously evolving core technologies and a global delivery infrastructure, we export to key markets in Europe, America, Japan, South Korea, and Southeast Asia, providing reliable and efficient energy storage solutions to customers worldwide.

Driving the future withInnovative energy storage solutions.

-

40

Billion

Annual Production -

50000

Square

Meters Factory -

10

Certification

Certificates -

10

Years

Experience

Leading High-Quality Battery Manufacturingwith Advanced Technology

-

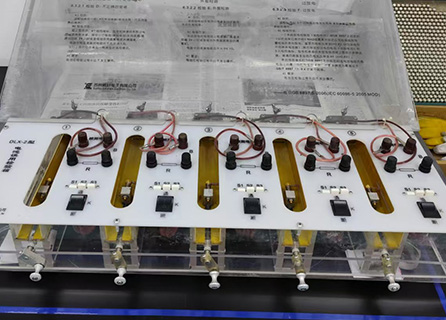

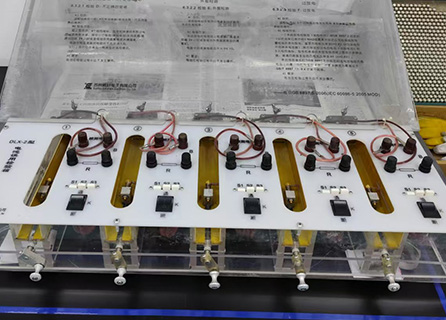

Advanced Manufacturing Facilities

Guangzhou Victory Technology Co., Ltd. has 23 international standardized production lines, integrating MES manufacturing execution system and industrial Internet of Things technology, realizing digital control of the entire process from raw materials to finished products, and creating an efficient and flexible modern battery production system.

-

High-quality Materials and Strict Assembly Process

Selected leak-proof battery core materials and corrosion-resistant shells, combined with high-precision welding and vacuum packaging technology, and visual inspection to ensure that the error of each assembly process is less than 0.02mm, significantly improving battery safety and durability.

-

Modern Production Complex

Build a three-in-one production system of "digital modeling-intelligent scheduling-real-time monitoring", integrate ERP resource management, automated logistics and energy efficiency optimization systems, and achieve large-scale intelligent operation with an annual output of more than 2 billion batteries

-

Advanced Manufacturing Facilities

Guangzhou Victory Technology Co., Ltd. has 23 international standardized production lines, integrating MES manufacturing execution system and industrial Internet of Things technology, realizing digital control of the entire process from raw materials to finished products, and creating an efficient and flexible modern battery production system.

-

High-quality Materials and Strict Assembly Process

Selected leak-proof battery core materials and corrosion-resistant shells, combined with high-precision welding and vacuum packaging technology, and visual inspection to ensure that the error of each assembly process is less than 0.02mm, significantly improving battery safety and durability.

-

Modern Production Complex

Build a three-in-one production system of "digital modeling-intelligent scheduling-real-time monitoring", integrate ERP resource management, automated logistics and energy efficiency optimization systems, and achieve large-scale intelligent operation with an annual output of more than 2 billion batteries

-

High Productivity and Efficient Production Lines

Using high-speed lamination technology and parallel production line design, the key process cycle is optimized to 1.2 seconds/unit, and with the AGV unmanned handling system, the production efficiency is increased by more than 40% compared with the traditional model

-

Strong Manufacturing Capacity

Relying on smart factory clusters and modular production line layout, it supports flexible production of multiple categories of alkaline/carbon batteries, with a daily production capacity of over 6 million units, and can quickly respond to customized needs of global customers.

-

Cutting-Edge Technology and Equipment

Integrated 3D process simulation system, laser precision welding robot and nano-coating technology, the battery internal resistance is reduced by 15% and the capacity density is increased by 20%, continuing to lead the industry's technical standards.

-

High Productivity and Efficient Production Lines

Using high-speed lamination technology and parallel production line design, the key process cycle is optimized to 1.2 seconds/unit, and with the AGV unmanned handling system, the production efficiency is increased by more than 40% compared with the traditional model

-

Strong Manufacturing Capacity

Relying on smart factory clusters and modular production line layout, it supports flexible production of multiple categories of alkaline/carbon batteries, with a daily production capacity of over 6 million units, and can quickly respond to customized needs of global customers.

-

Cutting-Edge Technology and Equipment

Integrated 3D process simulation system, laser precision welding robot and nano-coating technology, the battery internal resistance is reduced by 15% and the capacity density is increased by 20%, continuing to lead the industry's technical standards.

-

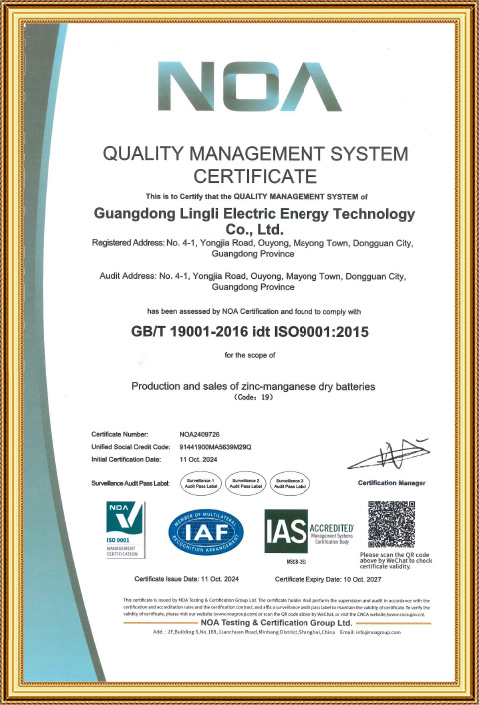

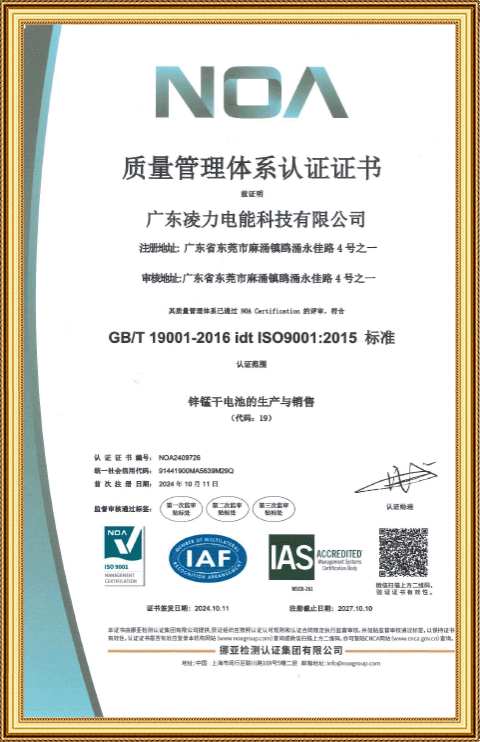

Strict Quality Management System

Passed ISO9001 and IEC international dual certification, established 128 inspection processes from raw materials entering the factory to finished products leaving the warehouse, and the product qualification rate reached 99.98%, ensuring zero difference in batch quality.

-

Advanced Testing Equipment

Equipped with X-ray nondestructive flaw detector, electrochemical performance test chamber and high and low temperature cycle test chamber, simulate extreme environment to verify battery performance and ensure that each batch of products is 100% in compliance with GB/T 8897.2 national standard

-

Leading Battery Manufacturing Factories

The company's batteries are produced and inspected according to the international IEC standards, and an intelligent quality management system has been established. The products have been recognized by the national technical supervision department and highly praised by the majority of users for many years, and the production and sales volume has maintained rapid growth. The company's batteries have won the support and love of all sectors of society with their strong power, good leak-proof performance, and durable characteristics.

-

Strict Quality Management System

Passed ISO9001 and IEC international dual certification, established 128 inspection processes from raw materials entering the factory to finished products leaving the warehouse, and the product qualification rate reached 99.98%, ensuring zero difference in batch quality.

-

Advanced Testing Equipment

Equipped with X-ray nondestructive flaw detector, electrochemical performance test chamber and high and low temperature cycle test chamber, simulate extreme environment to verify battery performance and ensure that each batch of products is 100% in compliance with GB/T 8897.2 national standard

-

Leading Battery Manufacturing Factories

The company's batteries are produced and inspected according to the international IEC standards, and an intelligent quality management system has been established. The products have been recognized by the national technical supervision department and highly praised by the majority of users for many years, and the production and sales volume has maintained rapid growth. The company's batteries have won the support and love of all sectors of society with their strong power, good leak-proof performance, and durable characteristics.

Certificate

History

Driving Innovation &Sustainability for a Green Future

-

Global Reach with Strong Production Capacity

With 12 international production bases and an annual output of 40 billion units, Guangzhou Victory Technology Co., Ltd. provides reliable energy storage solutions globally.

-

Leading Innovation in Energy Storage R&D

We specialize in cutting-edge energy storage solutions, continuously advancing with our SCT, AVR, and LiTi battery series, supported by our dedicated R&D facilities across the world.

-

International Certifications for Quality Assurance

Our products meet global safety and quality standards, certified by KC, CB, CE, PSE, FCC, RoHS, and UN38.3, ensuring top-tier reliability and customer satisfaction worldwide.